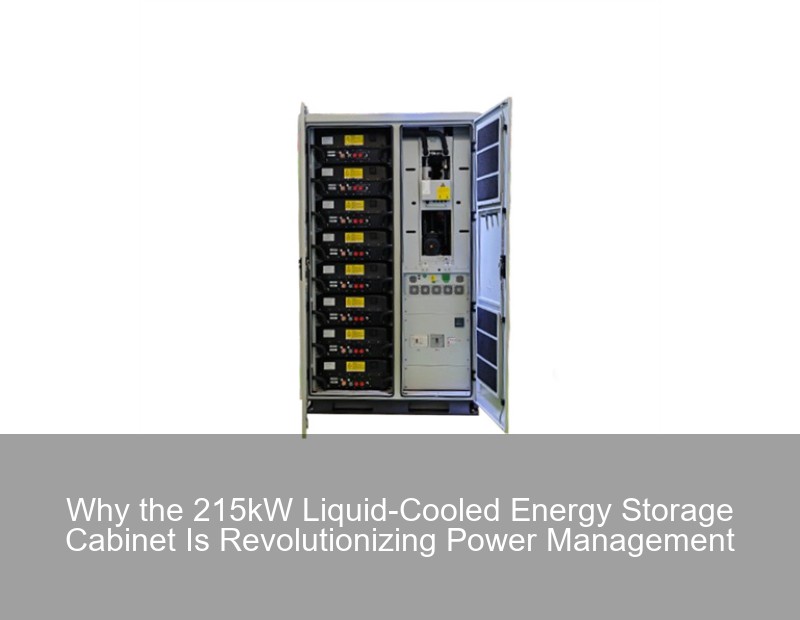

Why the 215kW Liquid-Cooled Energy Storage Cabinet Is Revolutionizing Power Management

The Hidden Crisis in Traditional Energy Storage Systems

Did you know that up to 15% of stored renewable energy gets wasted due to inefficient thermal management in conventional battery cabinets? As global renewable capacity approaches 4,500 GW according to the 2024 Global Energy Outlook, this thermal inefficiency translates to $6.7 billion in annual losses industry-wide .

3 Critical Pain Points Driving Market Change

- Thermal runaway risks increase exponentially above 35°C cell temperatures

- Air-cooled systems consume 20-25% of stored energy for temperature control

- Standard cabinets lose 1.2% storage capacity monthly due to temperature fluctuations

Well, here's where liquid-cooled systems change the game. Let's break down why the 215kW cabinet specifically solves these issues.

Technical Breakdown: 215kW Liquid-Cooled Cabinet Specifications

| Parameter | Specification |

|---|---|

| Coolant Type | Dielectric fluid with 3x thermal conductivity of air |

| Voltage Range | 1,000-1,500 VDC (compatible with latest LiFePO4 batteries) |

| Cycle Efficiency | 96.5% @ 1C rate (vs 89-92% in air-cooled) |

Case Study: HyperStrong's Königssee Project

In March 2025, HyperStrong deployed 18 units of 215kW cabinets in Bavaria, achieving:

- 99.98% uptime during winter peak demand

- 15% higher energy density than project requirements

- 3-hour emergency backup without active cooling

Their secret sauce? A hybrid cooling architecture that combines phase-change materials with liquid circulation .

4 Emerging Applications Driving Adoption

1. Data Center Backup Systems

With hyperscalers requiring 99.9999% reliability, liquid cooling prevents thermal throttling during 50kW/server rack operations.

2. EV Fast-Charging Hubs

The 215kW cabinet's 750V architecture enables simultaneous charging of 6 vehicles at 125kW each - perfect for highway rest stops.

3. Offshore Wind Integration

Salt-resistant aluminum alloy enclosures allow deployment within 500m of coastlines - crucial for Germany's North Sea wind farms.

4. Industrial Microgrids

Seamless integration with hydrogen fuel cells creates self-sustaining systems for remote mining operations.

Future-Proofing Your Energy Strategy

As grid operators phase out lead-acid systems by 2028 (per EU Directive 2023/517), the 215kW cabinet's modular design allows gradual capacity expansion. Its CAN bus communication protocol supports real-time SOC adjustments based on electricity pricing - a must-have feature with spot prices fluctuating 300% daily in some markets.